These are GEC Control Valve Actuators which have the job of controlling a steam turbine back pressure for the site process and power generation.

Our task was to fully refurbish these units and bring them back to their new life. It took a lot of fine planning to accomplish a great outcome and to meet our delivery deadline back to site.

As you can see the units were received in a fairly bad state externally and internally when pre-tested a number of issues were found with two units not working and the others having poor performance.

Our remit was to strip, clean and inspect all components of each actuator. Then to produce a detailed report listing all findings and recommendations plus photos and dimensional checks.

Once our reports were submitted and authorized, careful and timely planning was undertaken to ensure this project was kept on track.

Replacement parts were selectively sourced and manufactured and all 6 units meticulously rebuilt.

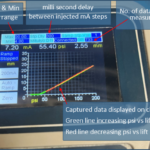

When fully reassembled, final test was carried out by mounting the actuator on our hydraulic test stand and connecting supply and control oil. The test stand oil was warmed to 60 degrees C and purged three times. Then calibration checks and adjustments carried out to OEM specifications and values recorded with our bespoke multi calibrator.

All 6 units were then safety delivered back to site by our EGS transport.

- Actuator in stripped form

- EGS bespoke multi calibrator readings

- Actuator on test bed

- Actuator in received state

- Actuators as received