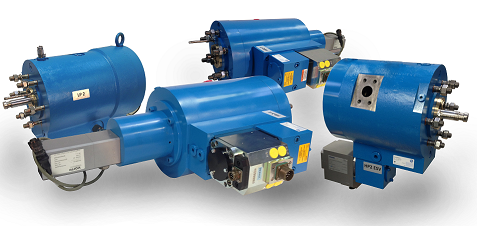

We have just completed another successful overhaul job of 4 large steam valve actuators and Voith Way Valves for steam turbines situated in a recycling plant. This particular plant recycles domestic waste into electrical energy, which subsequently exports to the National Grid.

This job was interesting for our engineers, as all 4 actuators were received in a stripped and broken down state, as the plant engineers had tried to examine the actuators themselves and in turn had severely damaged vital components on the 4 units.

After all components were chemically cleaned and stripped of any paint, they were then fully inspected to see the extent of the destruction. Major components were replaced as well as ‘O’ rings, piston rings, seals, receptacles and all consumable fasteners renewed.

Our machine shop carried out bore honing to suit over sized pistons. Grinding and re-chroming piston stems to standard size. We also manufactured piston bearing/ seal housings.

Each steam valve actuator uses a Voith Way Valve, so these were also overhauled. The ‘Way Valve’ controls the hydraulic pressure, monitoring the feedback (LVDT) positioning sensor for each valve when fitted to the steam turbine.

Once all units were carefully re-assembled and painted a vibrant blue colour, they then had to be tested. Our Applications Engineer has built customised test equipment to aid in the examination of the output figures that each complete actuator should read. The Voith over speed trips were tested to factory settings. Each unit took approximately 2 hours to gain full accurate readings.

On completion of test, all equipment was delivered to site by our EGS Engineers, who were on hand to assist with installation.

With a lot of careful planning and production meetings, EGS were able to complete and turnaround this job in 4 weeks.

Essex Governor Services

Experts in Mechanical Governing Worldwide